SHOP

You MUST Be 18 or over to purchase our knives. Please be sure to read our Disclaimer.

T.KELL KNIVES

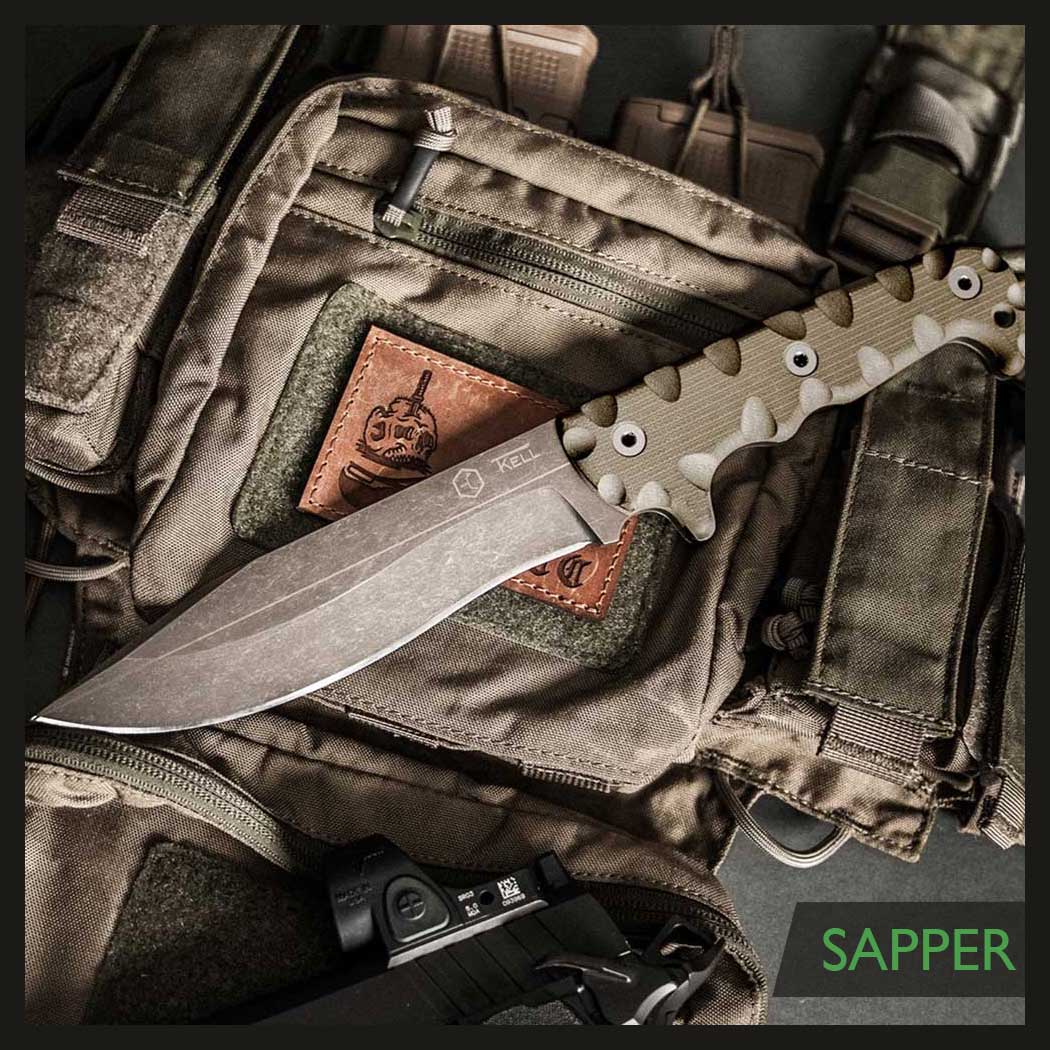

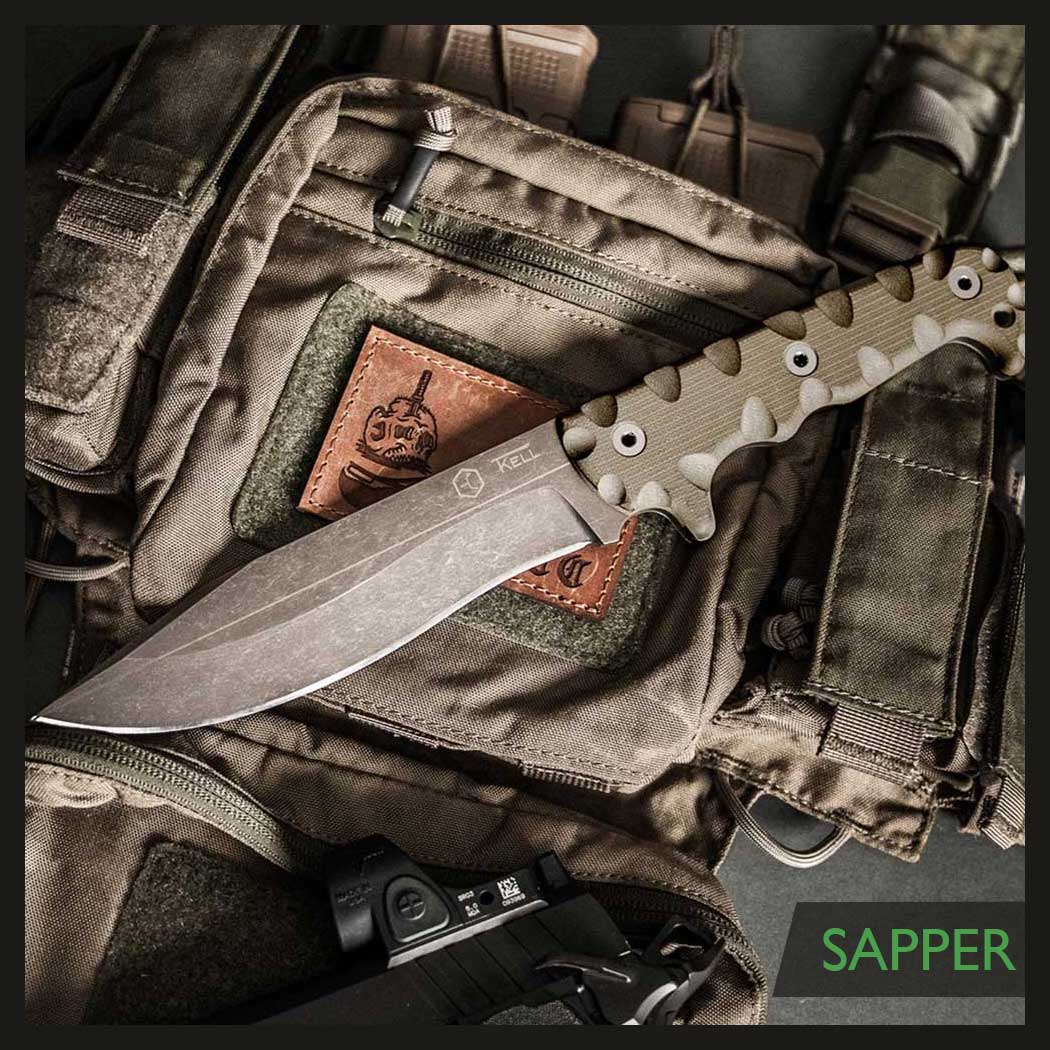

Sapper

Sapper

Couldn't load pickup availability

Reservations for the next batch opening 01 April 2024

Allow 3-6 Months for delivery. THIS IS A RESERVATION

Sapper

Sap·per

- : a military specialist in field fortification work (such as sapping)

- : a military demolitions specialist

Since the dawn of recorded time men have been fighting. As disputes grew between villages and territorial conflicts rose, those opposing views created separation. Armies were formed and the Warfighter born. There has been a need for warfighters to clear obstacles on their way to combat. As combat has become more advanced, so has the need for tools tailored to the modern warfighters' kit.

Using their combined warfighting, blade making, survival, and combat skills Tim Kell of T,Kell Knives (U.S.M.C.) and Imri Morgentstern of Prime Combat Training and Tactical Rifleman (I.D.F. Operator) teamed up to create an elite blade designed for the demands of the Warfighter, Civilian Solider, Survivalist, Bushcrafter, and Hunter alike. Whether it’s clearing roads, digging tunnels, penetrating fortifications or clearing land mines the Sapper excels in every environment you can throw at it. We didn't stop at just the warfighters needs, we designed a do all blade that is equally at home on your hiking pack as it is on you Plate carrier. Perfected for crafting shelters, cleaning game, clearing brush, wood splitting and camp chores the Sapper will preform the task better than any blade you've used. Built for a lifetime of battlefield level abuse and backed by our 'Life Of The Knife' warranty. Whatever the task is the “Sapper” must be with you.

The Sapper is purpose designed to facilitate the rough use required not only as a fighting and survival knife but as a delicate mine probe as well. Locating and exposing (in some cases neutralizing) land mines is an arduous and delicate task that requires a craftsman’s touch. When probing for mines the knife is held differently in order to transmit feedback from the ground (tip) to the operator’s palm (back of the knife grip). The punyo or pommel of the knife is rounded to fit comfortably at the base of your palm while allowing the pinky and/or ring finger to wrap around the “pinky guard” in order to maintain control of the tool. No more wrapping foam and duct tape around the pommel of your knife!!! Despite being very pointy the tip of the blade is as geometrically reinforced as can be without degrading penetrating power.

The alignment of the center of the pommel to the tip of the blade gives you an intuitive feeling of the exact point of probing in the ground. The etched line on the sides of the blade help with a visual reference as well. A wisely placed lanyard hole keeps your grip free of entanglement and also lends itself well to certain techniques of securing the knife.

The Sapper has slight recurve on a 6” cutting edge. This makes this an aggressive chopper with a center of balance just ahead of your first finger, this big blade feels fast and nimble while being incredibly strong for prying, point driven work, and heavy chopping. We even took the time designing a tip to give you the feel you need for mine probing but has the piercing ability of a true combat blade.

We selected AEB-L steel for the Sapper. With a carbon content higher than most "high Carbon" steel the Sapper will take a hair popping edge but has the grain structure to be incredibly durable for heavy use. AEB-L was specifically designed as a knife steel to take an incredibly sharp edge but also have the durability typically found only in non stainless high carbon steels. AEB-L has the perfect mix of Corrosion resistance and toughness you need for a battlefield level tool that you can rely on without the worry of extra care.

We clad the Sapper in our worlds first NiB T1C (Nickel Boron Tier 1 Coating). NiB is common the the Firearms industry. It is used to add extreme wear resistance and lubricity to the steel. It uses a process that isn't on top of the steel but becomes part of the steels surface. The addition of the NiB T1C coating makes the Sapper fly thru cuts due to its extreme lubricity and because NiB was developed for high speed bearings it can with stand temperatures and scratches better than ANY blade coating on earth. The T1C is a proprietary mixture of NiB and NiP (Nickle Phosphorus) giving you a corrosion resistance 400 times greater than other NiB coatings.

I know we keep talking about the innovation built into the Sapper but we worked so hard to bring a revolutionary blade to market that we feel we owe it to you to share every aspect of what makes this blade truly remarkable. We included a lock on the kydex sheath to keep your blade so secure that Jumps from planes are no worry at all. Simply slide the knurled knob up to lock the blade into your sheath or keep it in the unlocked position for standard retention. We removed all unnecessary material that you find on competitors sheaths that make theirs sheaths bulky, hard to mount, and unnecessarily wide. The added drain holes ensure your blade dries fast in the sheath. We've also added slots and multiple rivet holes spaced for multiple mounting options using the common aftermarket mounts.

We used our proprietary and now famous lashing screws to lock the G10 grips onto the blade. The lashing screws allow you to remove your grips for cleaning, swap them to a different color and pass paracord thru the center to give you a more secure way to tie your blade to a pole for spear making or lanyard loops. The unique texture we put on the surface of our grips plus the grenade grip "scallops" make T.Kell grips feel like they grab you back and lock you onto the blade without out creating hot spots.

One of the most important things here a T.Kell is making blades with next level performance no matter what it takes to get it done right. Part of that is our overly detailed heat treatment process that includes the undisputed best, most accurate method for heat treatment called salt bath. In short Salt Bath heat treatment uses molten salt heated to the steels exact correct hardening temperature. This prevents any possibility of over or under heating the steel in spots which destroys the steels structure like the cheaper gas or electric oven methods. Factually ovens have hot and cold spots and Salt bath doesn't. We also take extra steps to do a deep cryogenics treatment to increase the ductility and toughness of the blade. Deep cryo is -330 degrees for over 24 hours, other companies will do a quick subzero quench and call their process cryogenics. Deep cryogenics (what we do) is different because the structures of the steel don't reach their maximum potential until after 24 hours below -300 degrees. Does all this take longer? Yep, but it makes a blade light years better.

The Sapper truly is an heirloom quality, incredible blade that you can depend on for a lifetime and hand down for generations to come. We stand behind that for the life of the blade regardless of ownership.

- Full Tang Fixed Blade

- 12” overall length

- 6” cutting edge

- 1.5" wide blade

- 5.5" grip

- 13.7oz knife only; 18.8oz w/ sheath

- Finger guards front and back accommodate high grip or chopping (pinky)

- Pommel shape is optimized to comfortably nest in the base of the palm and be held by a pinky/ring finger

- Reinforced tip

- 3/16" thick 60 HRC cryogenically treated AEB-L Steel

- 3 hole lashing screws for different lashing options

- Etched line from tip to the handle to help visualize tip contact underground

- Balance point just ahead of guard, making it a great chopper

- Safe finger choil for higher grip (delicate cutting)

- G10 scales cover all contact surfaces with hand

- NiB T1C clad for extreme durability

- Matte grey finish for clandestine OPS